Jacket rolls with a multi-tube structure are manufactured through various processes such as material arrangement, heat treatment, machining, welding, grinding, hard chrome plating, and mirror finishing.

We strive to maintain high quality roll production by conducting welding and non-destructive inspection by qualified personnel.

We will guide you through the process from ordering to product completion.

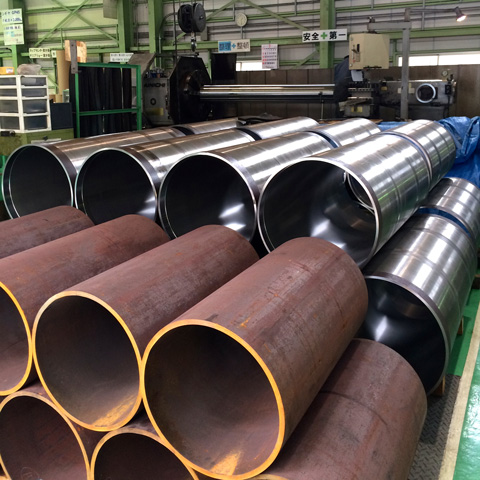

When an order comes, we take the design drawing from the custmer and then arrange necessary materials.

Scroll

We process parts with various machines.

Welding and assembling the processed parts.

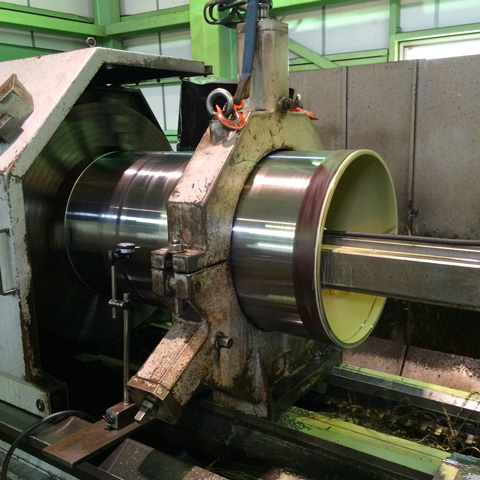

We finish it up with the lathe before the abrasive processing.

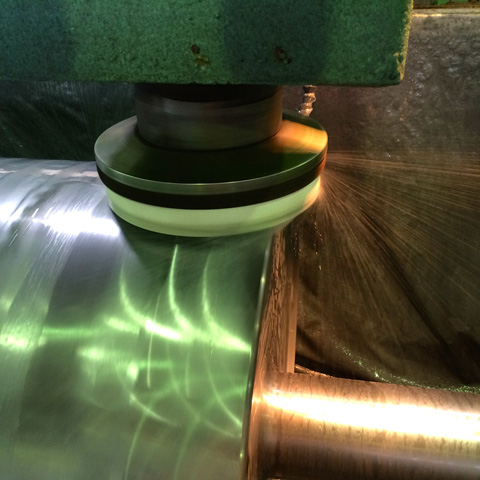

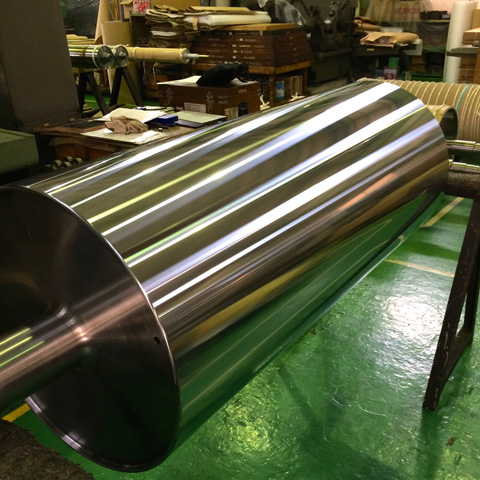

We polish with cylinder grinding - mirror polishing. We do this step again after plating depending on the surface roughness.

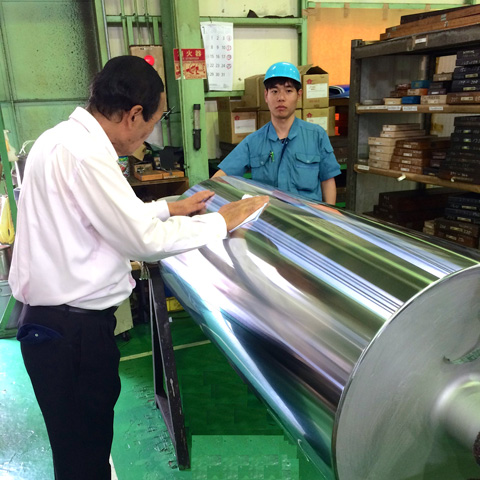

Final inspection. We execute the 100% inspection. Appearance of witnessed inspection of customer.

Completion. (A photograph of the completion of φ600 with plating of 30μ 1.6s )

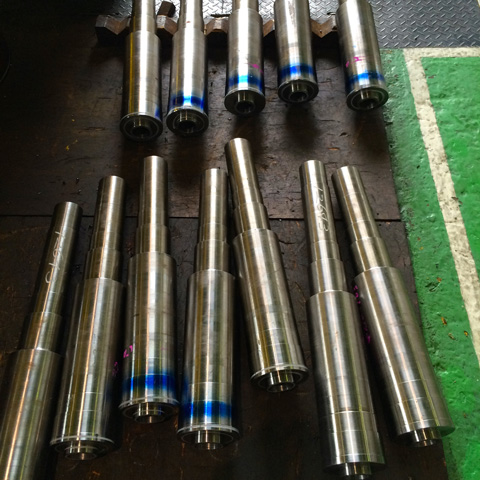

Roll Shaft

The previous page introduces roll production.

Shaft production is introduced on the next page.